Shackle reversal is one of the most misunderstood Jeep suspension

modifications. Most people do not really understand the advantages

and disadvantages of shackle reversal. The pros and cons of shackle

reversal should be understood before you spend your hard earned

money on a kit.

Some argue that if shackle reversal was so great, why didn't they

make Jeeps with reversed shackles from the factory? Well they did,

the military version of the CJ-5, the M38A1 always had the shackle

to the rear. The CJ always had the shackle forward there and it

is hard to decide whether Jeep engineers were just unwilling to

try new things or intentially built civilian Jeeps shackle forward.

Handling

The purpose of a shackle reversal is to allow the tire move backwards

easily when it hits a bump to smooth out the ride. That is the

theory at least, but it is important to understand how the axle

moves with various spring combinations in order to really understand

the handling advantages and disadvantages.

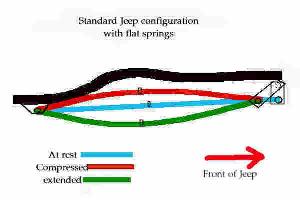

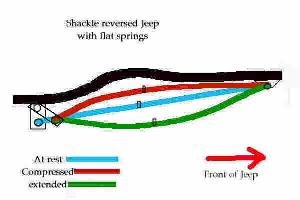

Axle Movement With Flat Springs

When measuring spring length, one normally measures spring eye to

spring eye. Obviously, springs do not shrink and grow, but the

distance between the eyes changes when they flex. Flat springs are

at their maximum length at rest and any flex decreases the distance

between the eyes.

With flat arch springs on a CJ or YJ with the conventional setup the

tire already goes backwards as it goes up, in fact it also goes

backwards as it goes down. This is because the spring is it's longest

when it is flat and curving it either way shortens the spring and draws

the tire towards the fixed end. This can be demonstrated on any stock YJ

by noting the angle of the shackle relative to the frame when it is

sitting on flat ground, and then again when one tire has been run up a

ramp. On the ramp the bottom end of both front shackles will be more

towards the rear than when on flat ground because one spring will be

arched positively and one negatively.

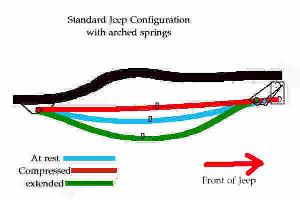

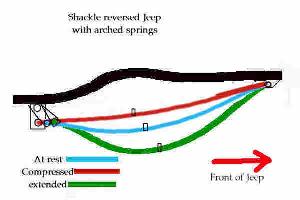

Axle Movement With Arched Springs

With heavily arched springs such as used in normal 4" spring under axle

lift kits and the conventional fixed spring hanger at the rear the front

tire will come forwards when it rises to go over a bump. This is because

the spring is moving towards being flat, rather than away from being

flat.

As the spring moves towards being flat the arch decreases and the

length of the spring increases, pushing the tire slightly forwards.

A shackle reversal puts the fixed end of the spring at the front, which

makes the tire go rearwards on compression instead of forwards. This is

very desirable for handling reasons. This is why shackle reversals are

popular with after market lift springs on YJs and CJs.

Bump Steer

Besides allowing for smoother motion over bumps, a shackle reversal

reduces bump steer. This seems a bit hard to imagine at first, but

if you look at the arc that the axle travels in with a shackle reversal,

you will notice that caster increases as the axle compresses. The

increase in caster makes the Jeep track better reducing wander on

bumpy roads.

Nose Dive

A Jeep with a shackle reversal and arched springs will suffer from more

front end dive during braking than a non reversed Jeep. The reason is

similar to the reason for the improved highway ride. When the brakes are

applied the tire is effectively pulled hard to the rear of the Jeep by

the braking force. On a Jeep with arched springs and a shackle reversal

the rearward pull will cause the springs to flatten out or compress. The

compression from the tire pulling back combined with the forwards weight

transfer that normally happens during braking cause the nose of the Jeep

to drop more than a non shackle reversed jeep.

With arched springs and no shackle reversal the force of the tire being

pulled towards the rear of the Jeep causes the spring to arch more. The

spring arching and the natural forwards weight transfer somewhat cancel

each other out and front end dive is limited.

The Driveshaft Problem

Another disadvantage of shackle reversal is the need for a drive

shaft with more travel. A long travel drive shaft is required

because the tire is going forwards as it goes down and backwards

as it goes up. The downward and forward movements add together

meaning a drive shaft used with shackle reversal must compress

and extend more than a shackle forward driveshaft.

If the drive shaft problem is not dealt with, parts can be broken.

A drive shaft that is too short will fall apart when droop is maximized.

A drive shaft that is too long can be punched through a transfer

case. Long travel drive shafts can be expensive and long travel

drive shafts wear quicker than short travel drive shafts.

If the drive shaft problem is not dealt with, parts can be broken.

A drive shaft that is too short will fall apart when droop is maximized.

A drive shaft that is too long can be punched through a transfer

case. Long travel drive shafts can be expensive and long travel

drive shafts wear quicker than short travel drive shafts.

With no shackle reversal and arched springs the tire goes forwards as it

goes up and rearwards as it goes down. The forwards and upward motions

partially cancel each other resulting in less of a length change on the

driveshaft. The same cancellation effect happens as the tire goes

rearwards and down. The result is a fairly normal amount of length

change on the driveshaft that the stock slip joint can usually

handle.

Tire Clearance

A Jeep with shackle reversal can have the tire move back more than

it would with the shackle forward. Clearance for tires should be

checked with a shackle reversal to make sure body damage does not

occur if a tire comes into contact with a fender.

Bull Dozing

A shackle reversal should not change the approach angle, but

it can be built so it slides over obstacles better. With the

shackles forward, if you hit a rock dead on, there is a possibility

of bending the spring and the shackle will not slide easily over

the rock. With a shackle reversal, the front mount can be ramped

so the spring pushes over the rock.

Bending Springs

A Jeep with a shackle reversal will be less likely to bend a spring if

the spring hits an obstacle. The liklyhood of bending a spring while

backing up will be increased with a shackle reversal, but most

of the time people are driving in the forward direction.

Tire Contact Pressure

A Jeep with the shackle forward will load the spring and tire

when the Jeep is driven into an obstacle. The spring and axle

do not move back, so traction is increased. With the shackle

reversed, contact pressure will be increase any time the front

axle is pushed forward. Here shackle reversal might have a slight

advantage when climbing steep hills where the axle wants to move

forward. Generally traction is not a problem when you come straight

on an obstacle in a flat area.

Conclusion

Both methods have their pluses and minuses. It boils down more

to what the rig's purpose is - and personal preferences. If the

Jeep is going to be a daily driver as well as weekend trail warrior,

forward shackles may be the way to go. If the rig is primary a

trail toy and sees more street miles on a trailer than with its

tires on the tarmac, then the rear shackles may be more advantageous.

Contributors

Thanks to Dave Gray for the top picture and some tidbits on shackle

reversal.